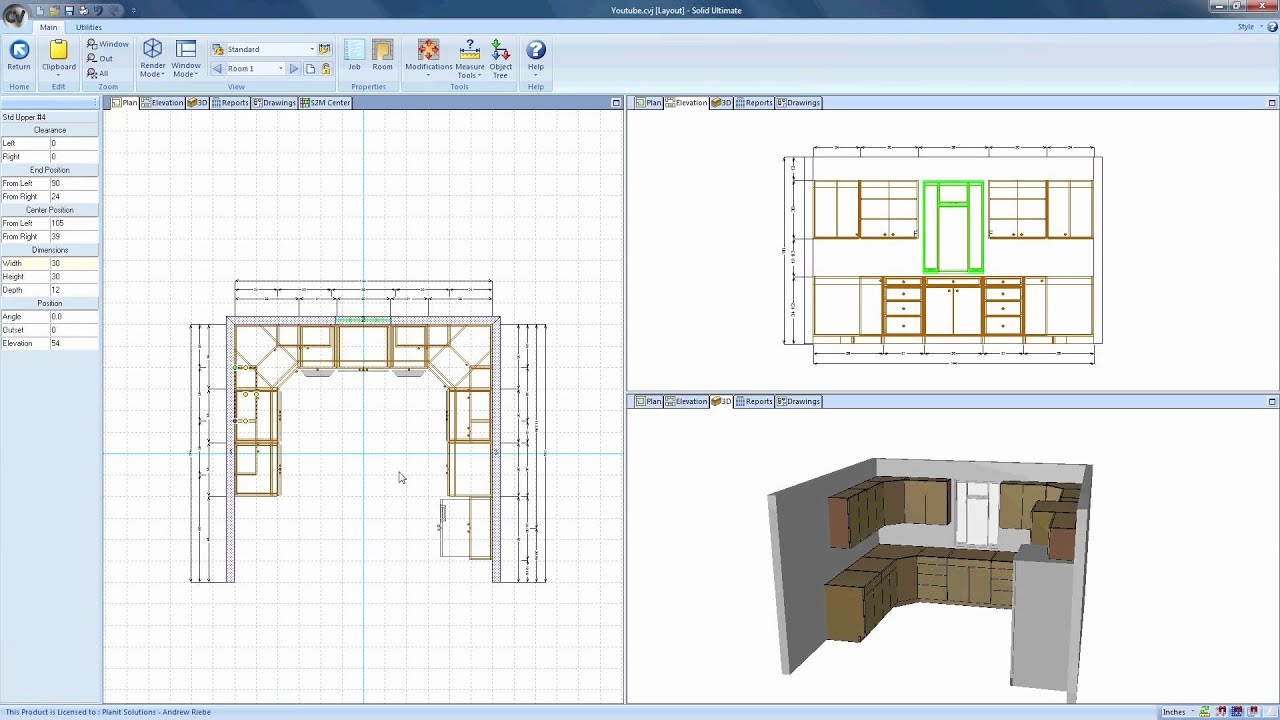

Cabinet Solutions is an easy-to-use design program for cabinet makers. Features include 2D/3D drawings, dimensioned floor plans & elevations, cut lists, door reports, job costing, a panel optimizer, and an optional CNC exporter.

I am working on a server running Windows Server 2003. I just installed the new version of a program - Solid 4.2 Solid 4.0 and Solid 4.1 are in separate files themselves, all under a directory called Planit (the name of the software company). During installation, it asked if it could lockout users in order to complete installation, and I was ok with that - it is a trustworthy piece of software. The S2M Center ™ is a core product that integrates with Cabinet Vision and Cabnetware. Geometry and machining data from Cabinet Vision and Cabnetware is automatically generated for virtually any CNC machine on the market. Tags: eCabinet Systems, artcam, 20-20, KCD, Microvellum, CabinetPro, RouterCAD, Planit, Cabinet Vision, CabinetWare, Mastercam, Alphacam, BobCAD-CAM Did you know that Thermwood CNC Routers are compatible with most major design and CAD/CAM software programs?

The top three reasons cabinet makers purchase a program such as Cabinet Solutions are:

- It would be devastating to lose KCD. It's part of our business from the moment clients sit down with us. Every project we do, we're using KCD to design and present it and send it to CNC.

- Tags: eCabinet Systems, artcam, 20-20, KCD, Microvellum, CabinetPro, RouterCAD, Planit, Cabinet Vision, CabinetWare, Mastercam, Alphacam, BobCAD-CAM Did you know that Thermwood CNC Routers are compatible with most major design and CAD/CAM software programs?

- A quick and easy way to preview your project via 3D & 2D drawings.

- A quick and easy way to accurately estimate job costs.

- A quick and easy way of accurately generating manufacturing reports such as cut lists, door lists, and panel optimizations.

We address these needs by providing a program that enables you to complete your initial layouts & revisions quickly, estimates job costs based on your real material & hardware costs, and generates a number of manufacturing-related reports to help build the job after your proposal is accepted.

Whether you rent or purchase, you still get the same capabilities (see software features below) in the standard program.

Software Features

- Part Labels

- Material Takeoffs

- Supports Inch and Metric

Software Applications

- Face Frame Cabinets

- Frameless Cabinetry

- Residential Cabinets

- Kitchen Cabinets

- Closets

- Entertainment Centers

- Garage Cabinets

- Other types of casework

RouterCAD is a commercial cabinet software suite that includes AutoCabinets, MillworkCAD, and RouterCAM. You can use it to design custom cabinets and custom single part woodworking projects then export G-Code for your CNC with the same program. It has a $1750 one-time cost.

div.slide'>

Cabinet Vision has products designed for the wardrobes and storage industry.

Learn More

With advanced CAD tools we have the right software for you.

Learn More

The power and flexibility you need to get the job done right.

Learn More

S2M Center lets you send your designs straight to your CNC machinery.

Learn More

Planit Cabinet Software

From entry level cutlist packages to four fully integrated Screen-to-Machine™ solutions, and every step along the way, CABINET VISION is the only software that can truly grow with your business. All of our modules include design, rendering, pricing and bidding, and cutlist and report capabilities.

Planit Cabinetware

Sunrise Wood Designs uses a masterful combination of talent and technology to serve the largest residential market in the United States.

Planit Cabinetware

The Test Drive Programme has been designed to give end users the chance to evaluate the use of a CAD/CAM system. A number of manufacturing firms are falling behind their global competitors by still relying on manual programming, or use inefficient CAD/CAM software to create CNC code.